Advances in Off-the-Shelf MWIR Imaging Systems Can Reduce Development Time by Two Years

MWIR and Continuous Zoom Lens Integrated Solutions

Midwave infrared (MWIR) cameras have long been the preferred solution for clear thermal image detail at distances greater than one kilometer (km) for defense, counter-UAS, security, UAS, and other long-range surveillance applications. To meet these imaging requirements, they are commonly integrated with a continuous zoom (CZ) lens assembly. Developing custom cameras and CZ lenses can be costly in terms of time and resources, and it can become complicated. However, recent technological breakthroughs in off-the-shelf solutions available for MWIR platform development now offer integrators significant cost savings, performance optimization, technical risk reduction, and schedule improvements. Integrators could see development-time savings of two years

or more.

Traditionally, integrators of MWIR imaging platforms were required to work with multiple companies to source the sensor assembly, optics, and electrical subsystem components. With Teledyne FLIR’s release of multiple new MWIR cameras and CZ lens assemblies starting in 2021, integrators now have access to off-the-shelf or semi-custom systems from a single manufacturing partner offering design, integration, service, and support advantages.

This paper reviews the traditional challenges of MWIR imaging platform design and illustrates how leveraging a single solution provider can reduce time to market, complexity, and affordability while also improving size, weight, and performance (SWaP).

Advances in MWIR Camera and CZ Lens Technology

Advancements in high operating temperature (HOT) MWIR sensors have enabled SWaP improvements at the camera system level, along with faster time-to-image, making HOT MWIR camera modules perfect for UAS, intelligence, surveillance, and reconnaissance (ISR), and man-portable applications such as weapon sights.

Equally important advancements have been happening with MWIR CZ lens technology. In contrast with visible zoom lenses, MWIR CZ optics have been traditionally complex and costly due to the exotic materials required and inherent challenges maintaining focus within the entire zoom range – especially while operating across a wide temperature range. Now with improved engineering design tools, new optical materials, and automated manufacturing techniques, integrators can enjoy the development of several new SWaP and performance optimized CZ lens assemblies.

Traditional Design Challenge

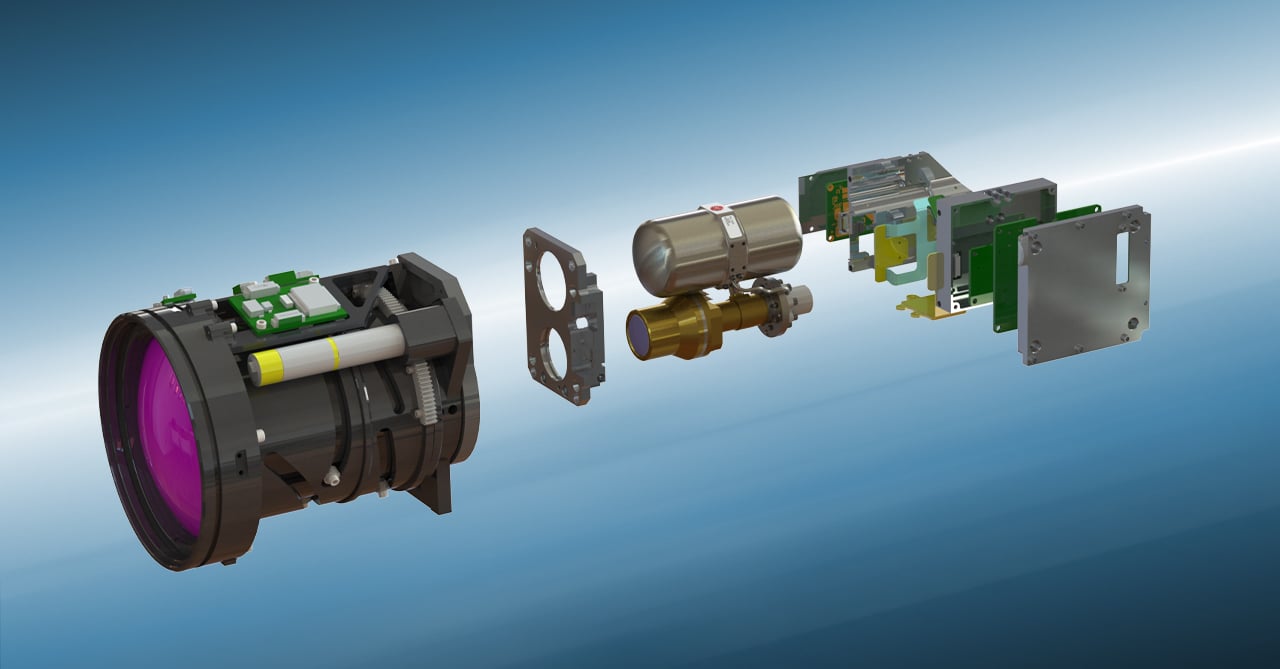

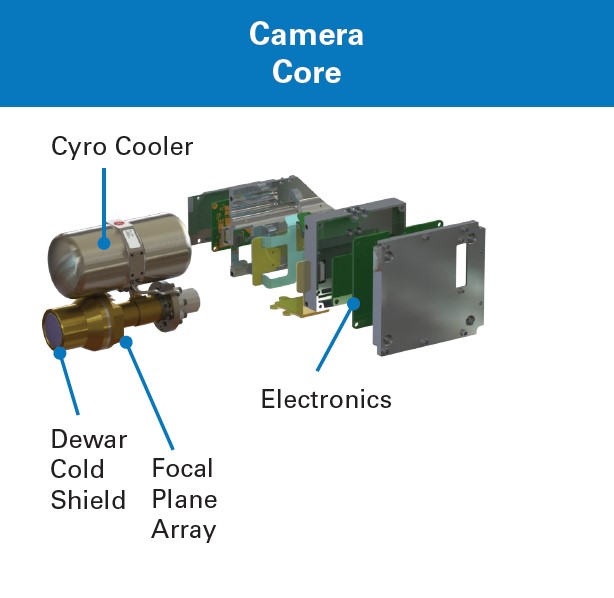

Figure 1. Exploded Assembly of the Teledyne FLIR Neutrino LC with Integrated 19-290 CZ Lens

A MWIR camera system consists of multiple subsystems. Moving from left to right (Figure 1), the continuous zoom optics determine the field of view (FOV), or optical magnification, to the camera. The lens collects and focuses the MWIR energy onto the focal plane array (FPA) packaged into an integrated dewar cooler assembly (IDCA). Camera electronics process the information from the IDCA into usable data or an image supporting the camera output as well as the command-and-control software.

The traditional method to procure and integrate these solutions often necessitated developing separate subassembly requirements and working with multiple sources to develop a MWIR CZ system. When developing separate subassembly requirements, integrators need to consider multiple performance parameters and consolidate them at the system level to support lens and IDCA vendors. See Table 1 below for example considerations. For well-resourced projects with unique requirements and longer timelines, this can work, but increasingly as with CMOS camera solutions, industry is recognizing the value of working with and procuring a solution from a single supplier able to provide an affordable, off-the-shelf, high-performance solution as quickly as possible.

In addition to the considerations described in Table 1, these MWIR imaging systems can also suffer reduced system performance and reliability due to compatibility tradeoffs. This leads to efficiency losses and unnecessary complexity in the system development process and integration, procurement, manufacturing, and eventual system support.

Table 1. Example Design Considerations for MWIR Cameras with CZ Optics

| ZOOM OPTICS | CAMERA & ELECTRONICS | SOFTWARE AND DRIVE ELECTRONICS |

| Performance over Temperature | Resolution & Pixel Size | Control |

| Mounting | Frame Rate | Data Interface |

| Focus Shift | Wavelength & f/# | Power Throughput |

| Tolerance Analysis | Image Processing | Camera Communications |

| Field of View & Zoom Range | Reliability (MTTF) | |

| DRI | Video Format | |

| Thermal Compensation | Size and Weight | |

| Range Compensation |

Integration and Support of Separate Subsystems

Following design, the integration of subsystems from multiple vendors can present additional challenges. Infrared CZ lenses are extremely complex and require precision alignment in five axes. This requires significant capital expenditure, potentially adding up to more than $400,000 through the purchasing of equipment such as collimators, temperature chambers, black bodies, MTF test equipment, and vibration testing stations. Highly specialized test technicians and engineers then must be trained and funded to support the integration. Software protocols can also differ for each subsystem driving complication for both integration and support.

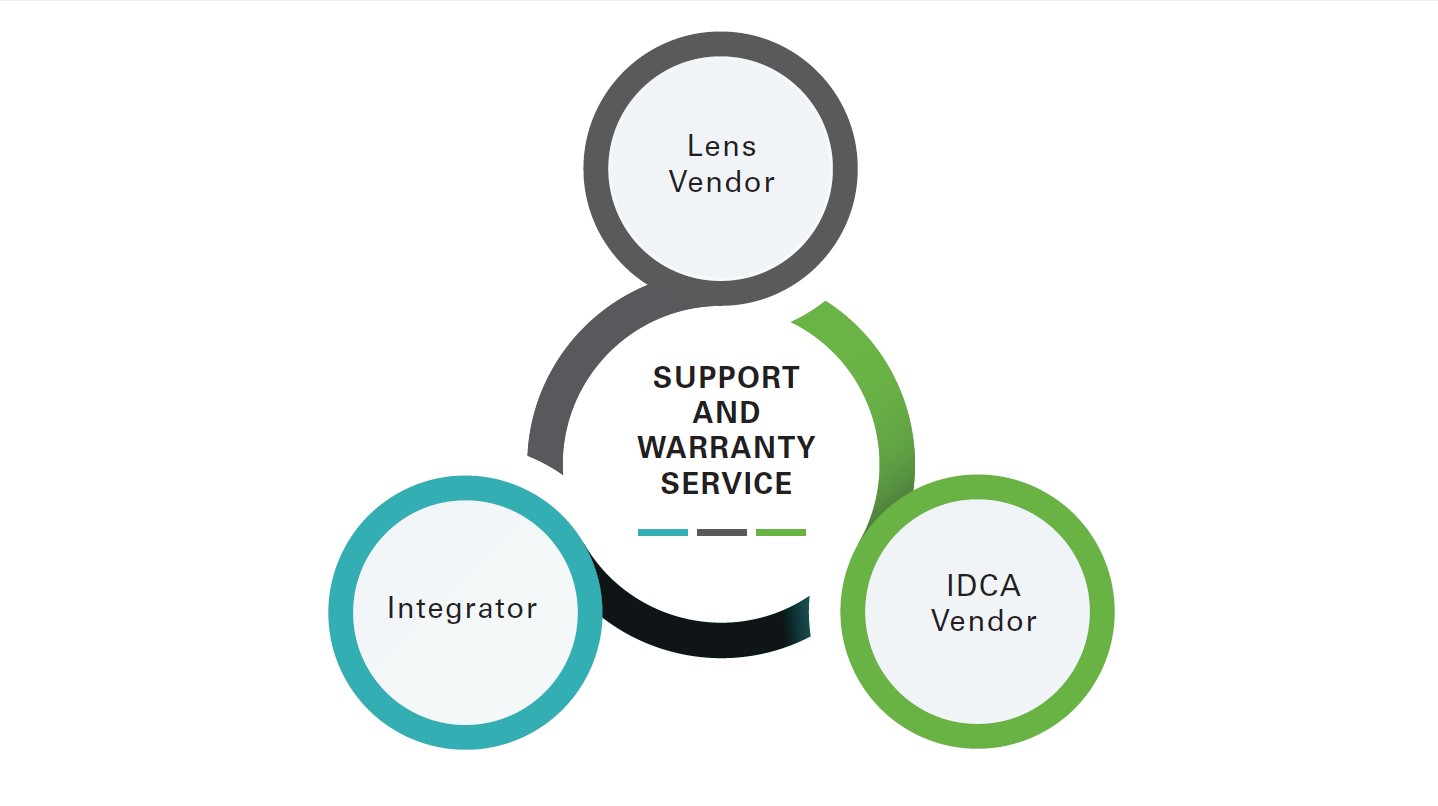

Once integrated solutions are in the field, support and service can also be difficult to execute. Generally, technical support to the customer must be handled by the integrator in conjunction with the IDCA and lens subsystem vendors to achieve satisfactory resolutions. A unit returned for service or repair must also be processed and dispositioned by the integrator before the relevant subsystem can be returned to the vendor for additional processing. This adds time and expenditure.

Figure 2. Support and Warranty Service Can Require Input from the Integrator and Key Suppliers

Off-the-shelf and Semi-custom Solutions

To summarize, an off-the-shelf solution, similar to the Neutrino® IS Series as opposed to developing a custom lens/camera solution, often provides a superior product due to the following advantages:

- Optimized SWaP, usability, and image performance

- Optics-to-camera tolerances ensure best-in-class boresight retention

- Simplified, common electrical and software controls eliminate interface issues

- Fewer moving parts, connectors, cables, and software SDKs

- Camera and lens are factory precision-aligned with and calibrated for peak image quality

- Single point of contact for all service and technical support

Teledyne FLIR can help customers determine which solution is right for their application from existing off-the-shelf options or given the Neutrino SWaP Series common interface, semi-custom solutions can be designed and integrated more quickly and at lower cost than a custom solution. This allows integrators to work with one supplier for solutions that include IR detectors, cooling engines, zoom lenses, camera/lens electronics, and packaging.

Figure 3. Teledyne FLIR’s Neutrino IS Series Portfolio (July 2022)

Figure 3. Teledyne FLIR’s Neutrino IS Series Portfolio (July 2022)

Go-to-market Impact

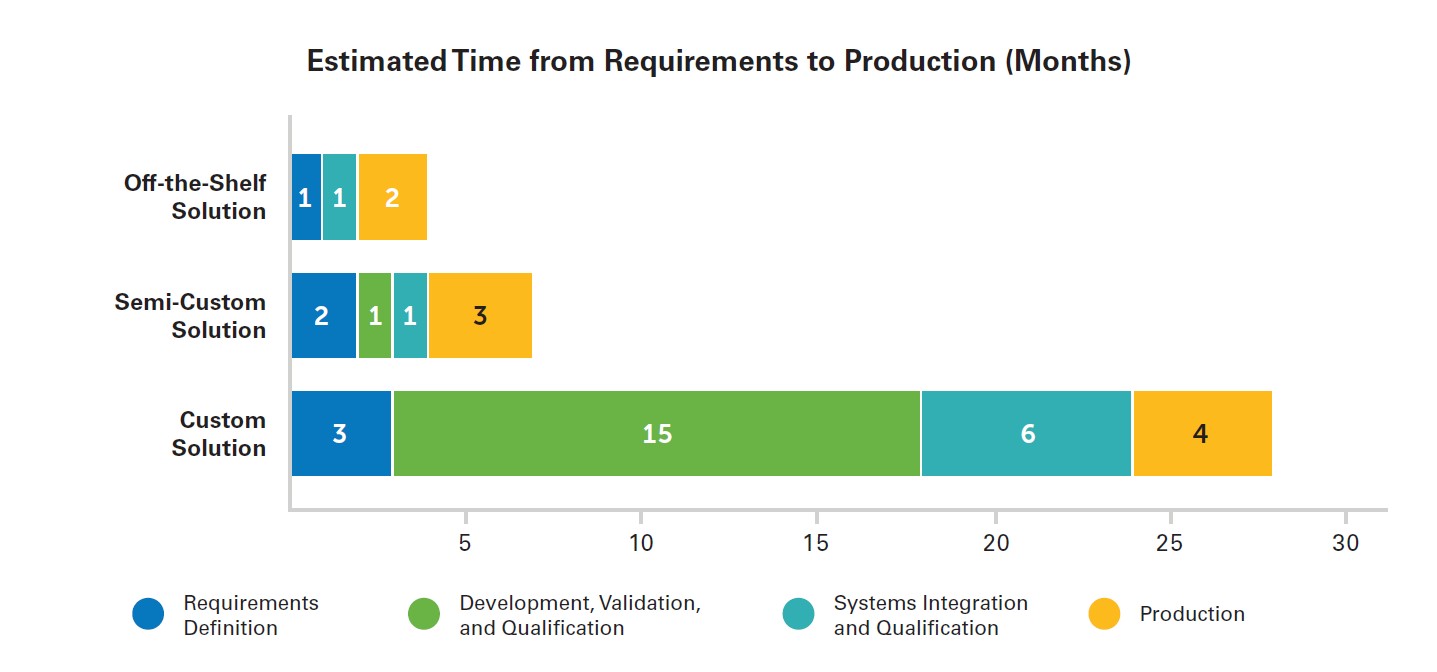

With access to a wide portfolio of off-the-shelf solutions available in potentially three to four months, depending on lead time, integrators can save significantly on time and development costs. Meanwhile, semi-custom solutions, which typically required approximately 18 months, can be acquired within six to nine months. In comparison, for acquisition programs with custom solutions, developers should plan for 24 to 30 months from requirements definition through final qualification. It is important to note that these custom solutions can be streamlined significantly by specifying requirements at higher assembly levels like those commonly available for commercial visible camera systems. Working with a single vertically integrated solution provider will result in a shorter design cycle, streamlined procurement process, and increased ability to create reliable solutions.

Click here to learn more about Teledyne FLIR high-performance MWIR cameras and solutions.

Figure 4. Comparison of Requirements, Development, Integration and Qualification for Custom, Semi-Custom, and Off-the-Shelf Solutions