Mining Equipment Inspections

Ensuring Uptime Through Condition Monitoring

Condition monitoring inspections and automated monitoring with fixed thermal imaging cameras allow mining companies to catch problems in their early stages—before equipment is compromised or destroyed and before costly accidents happen.

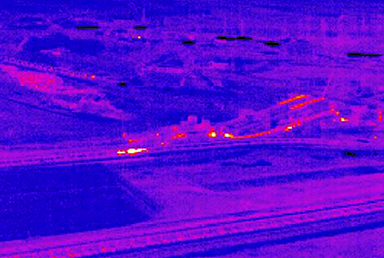

ENABLING REALTIME LIQUID LEAK DETECTION IN MINING SITES

The mining process produces chemicals that are both harmful and expensive. Using typical leak monitoring methods to find small liquid chemical leaks across a vast mining site can be labor-intensive and ineffective. Thermal imaging can spot these leaks within seconds, saving time and money.

LIMIT UNSCHEDULED DOWNTIME, IMPROVE WORKPLACE SAFETY

Thermal imaging allows for quick and thorough inspection of tires, pipes and other equipment at mining sites. This regular inspection means there is far less chance for equipment damage and costly accidents and far less chance for equipment to fail at inopportune times.

BATTLE ILLEGAL MINING

Thermal imaging improves mining security by offering 24-hour surveillance of properties. Infrared images identify intruders quicker and with far greater accuracy than other security methods.

Condition Monitoring Solutions for Mining Applications

FLIR A500f/A700f Advanced Smart Sensor

Fixed-Mount Thermal Imaging Camera for Condition Monitoring and Early Fire Detection

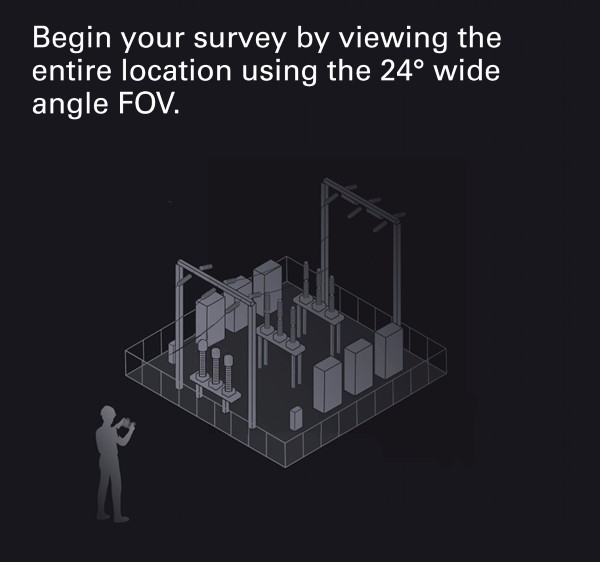

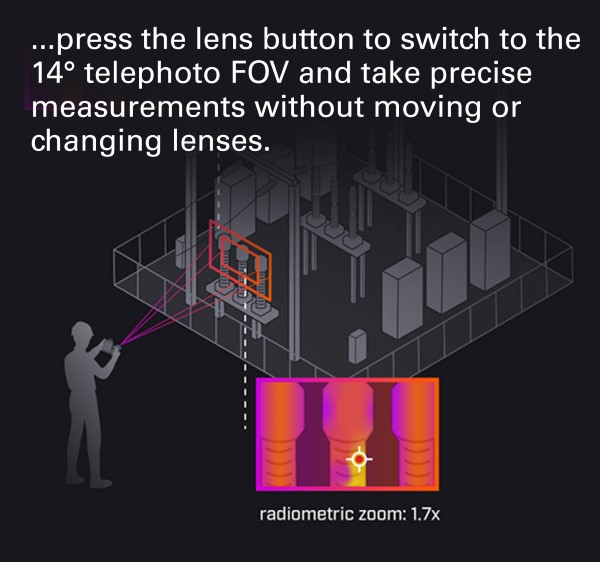

View ProductThe FLIR FlexView™ Lens

Designed to improve operational efficiency, safety, and accuracy

Streamline Inspections, Organize Data, and Manage Condition Monitoring Activites Across Maintenance Teams

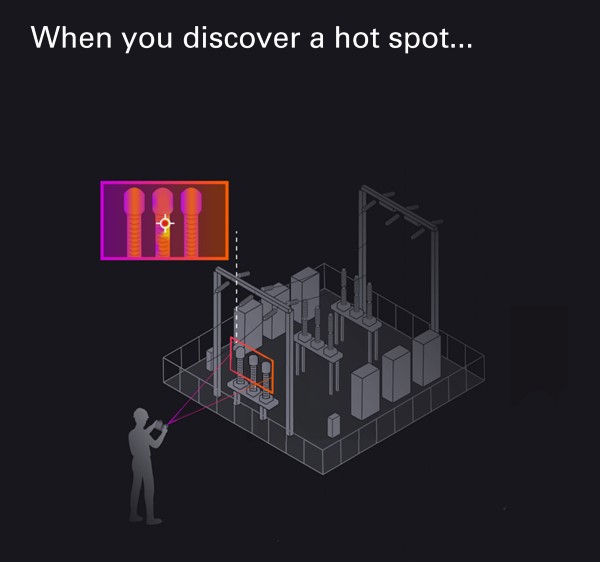

Whether you're working with a handheld thermal imaging camera, acoustic imaging camera, or optical gas imaging (OGI) camera, the best solution for organizing and managing inspection programs for the Mining industry is FLIR Thermal Studio Suite. This subscription software offers the organizational features and advanced processing needed for predictive maintenance on critical components, system troubleshooting, and increased productivity.

FLIR Thermal Studio Pro is a desktop software offering batch image processing, advanced image analysis, and access to FLIR Route Creator: a feature that lets users create their own inspection map and download it to a FLIR camera with Inspection Route enabled.

When paired with the FLIR IgniteTM cloud service for direct image back up, FLIR Thermal Studio software ensures accurate data collection that helps predictive maintenance crews spot problems before they cause critical failures.

INNOVATION IN ACTION

FLIR Thermal Imaging Enables Autonomous Inspections of Mining and Trucking Vehicles in Australia

Read the story

FLIR enables real-time liquid leak detection in the mining industry

Read the Story