Improving Productivity in the Food & Beverage Industry with Area Scan Cameras

The article focuses on the productivity benefits of Teledyne area scan cameras in the F&B industry. Area scan cameras capture the two-dimensional area of an object at once in color or monochrome making them a great fit for a variety of industry applications.

The food and beverage (F&B) industry is a fast-paced, demanding sector that requires efficiency and accuracy at every production stage. Optimizing productivity at various production stages such as food processing, packaging, quality control, or inventory management is also critical to success.

Teledyne’s imaging product portfolio ranges from image sensors and line/area/smart cameras to 3D laser profilers. Moreover, the AI-image processing software, Sapera Processing, significantly enhances productivity in the F&B sector.

Enhanced Image Acquisition Speed with Burst Mode and TurboDrive™.

F&B imaging applications such as high-speed food sorting, portion cutting, and quality monitoring are constantly looking to improve image capture speeds to reduce production cycle time.

Reduced Production Cycle Time = Cost Savings

However, the camera interface transfer bandwidth limits the image capture speed. A trade-off with a camera with a high transfer bandwidth interface is necessary. For example, a 10GigE interface camera requires a higher specification network system and power consumption, increasing the system's total cost.

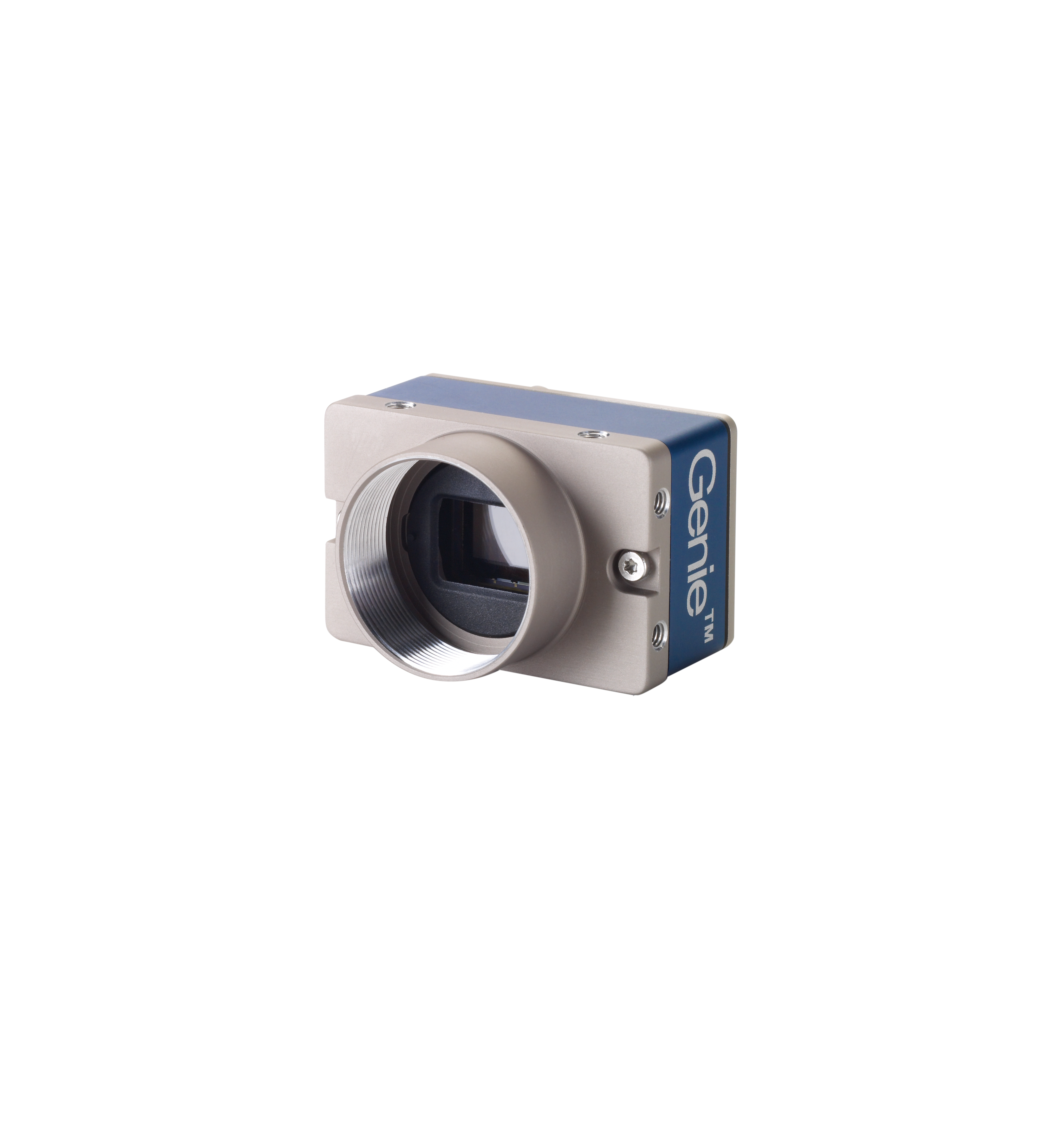

Teledyne’s Forge 5GigE*, Genie Nano-1GigE, and Genie Nano-5GigE provide innovative solutions, Burst Mode and TurboDrive™ mode, for rapid image acquisition and data transfer. These features double the original bandwidth speed under the 1GigE and 5GigE interface's limited bandwidth. The significant improvement in image acquisition and transfer speed reduces the system upgrade cost.

Versatile Functionality for Single Camera Application

The application of relying solely on a fixed area scan camera setting can sometimes make it difficult to capture an object's overall details. Additionally, a fixed-area scan camera captures an entire image even if a small area of the image object requires analysis. This results in lower transfer rate speed, higher data storage requirement, and higher image processing time.

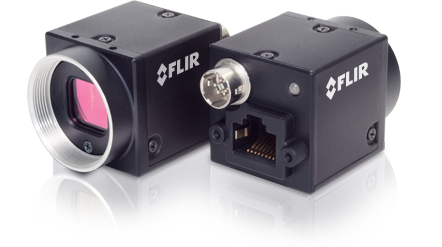

Teledyne’s Forge, Genie Nano, and Blackfly S cameras have features. Both Forge and Genie Nano offer advanced Multiple ROI functionality, which expands imaging capture capabilities even further.

- The Sequencer feature allows for consecutive capture of multiple images with variable camera settings.

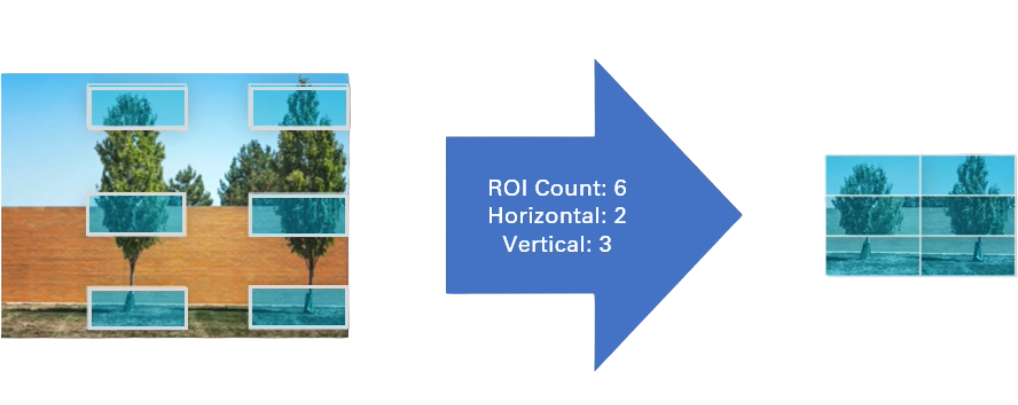

- The Region-of-Interest (ROI) feature enables capturing only one specific area of interest within an image frame.

- The Multiple Region-of-Interest (ROI) enables the capturing of multiple specific areas of interest within an image frame.

These advanced features allow for faster frame rates, reduced data storage requirements, and enhanced adaptability. This allows a single camera to offer versatility across a variety of F&B applications.

High Accuracy Triggering and Ultra-Precision Synchronization

Precision is paramount in the F&B industry, particularly in multi-camera systems where each camera connects to a network switch and is ready to receive triggering signals. The two most common precision issues are latency in image acquisition and variations in each image frame captured. These issues typically require manual intervention from the system designer or process engineer.

Forge and Genie Nano cameras have advanced capabilities such as the ethernet industry-standard IEEE1588 Precision Time Protocol (PTP), Optimized Action Commands, and Trigger-to-Expose start functions for precise triggering and synchronization. These features capture images without jittering lines and accurately synchronize across multiple cameras. This results in improved precision and efficiency for food container packaging inspection, palletizing systems, and food depositing applications.

Optimized Image Processing Efficiency with In-Camera Preprocessing

Maintaining high-quality standards for food processing and packaging requires correct color representation. Captured images are typically sent to the host computer for color processing and product quality analysis. In a scenario with multiple camera connections, the required host computer must have considerable processing power. This results in an increase in the system cost.

The Blackfly S camera employs in-camera color correction and preprocessing, reducing the computational load on the host system. These features help achieve consistent high-color accuracy imagery critical in maintaining quality standards throughout production.

Customizable Spectral Imaging for Detailed Analysis

In-depth food analysis uses multispectral and specific spectral imaging such as Near-Infrared (NIR) or Short-Wave Infrared (SWIR).

As SWIR camera solutions typically have increased costs, an alternative solution involves using a CMOS sensor with narrowband filters to attain the desired food image result. Teledyne’s Blackfly S cameras offer customizable filters and glass removals, allowing NIR spectrum capture using standard CMOS sensors. This customization facilitates detailed analysis for accurate decision-making in quality control and sorting applications.

Data Traceability and System Reliability

During the industry process, the vision systems must maintain seamless image data transfers and traceability to the host. Suppose there is an unexpected behavior in the imaging system. It will be difficult to determine the status of the complex imaging system and the validity of the captured image transfer.

All Teledyne camera models support metadata for capturing individual images, ensuring accurate image configuration tracking during entire high-speed processes.

In addition, the Teledyne area scan camera’s Trigger-to-Image-Reliability (T2IR) framework simplifies system debugging and error analysis through functional and statistical means. Also, The T2IR capability enhances system comprehension and prevents data loss. This is particularly beneficial in quality check tasks such as packing, sealing, label marking, and bottle-filling inspection.

In conclusion, incorporating Teledyne's area scan GigE cameras such as Forge, Genie Nano and Blackfly S with acquisition software solution, Spinnaker, can enhance efficiency, refine quality control, and deliver exceptional products to meet the dynamic needs of equipment builders and system integrators within the food and beverage industry. Teledyne designs state-of-the-art imaging technologies that empower businesses to maintain a competitive edge in the industry.